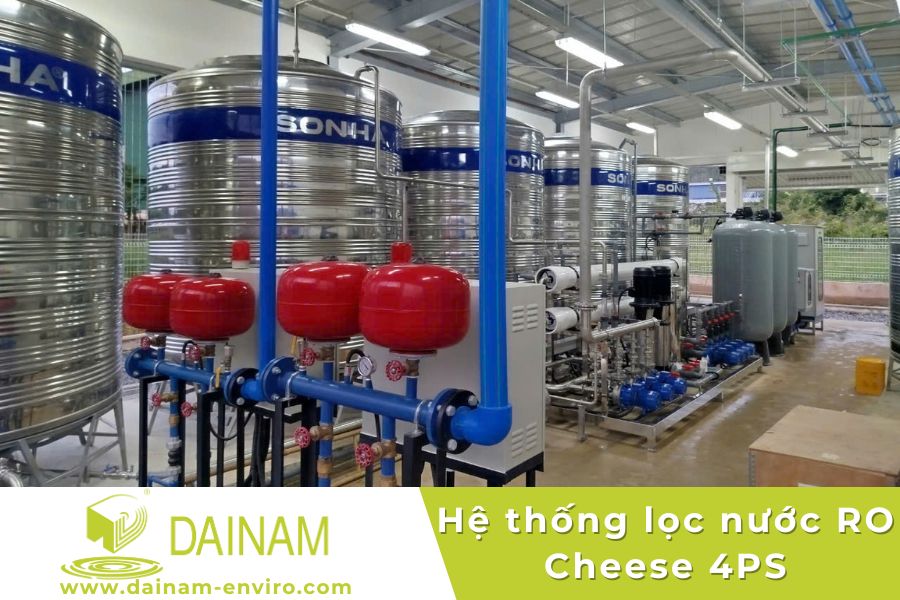

Dai Nam Environmental Solutions Company has successfully completed the installation of a 50m³/day RO water filtration system for Cheese 4PS Joint Stock Company. This system ensures a reliable water supply for both production and daily activities at the factory. The system is designed to meet strict environmental standards, featuring the latest modern equipment.

1. Project Information

-

Project Name: Cheese 4PS Dairy Factory

-

Investor: CHEESE 4PS JOINT STOCK COMPANY

-

Execution Unit: Dai Nam Environmental Solutions Company Ltd.

-

Location: Lot B1-8, Phu Hoi Industrial Park, Phu Hoi Commune, Duc Trong District, Lam Dong Province

-

Capacity: 50m³/day

-

RO Water Quality Standard: The treated RO water meets QCVN 06-1:2010/BYT standards.

RO Water Filtration System at Cheese 4PS Factory

2. Technology Diagram

The RO water filtration system is implemented by Dai Nam according to the following diagram:

.jpg)

2.1. Raw Water Tank T01

The raw water supplied, meeting the QCVN 02:2009/BYT standards, is pumped into the 10m³ raw water tank (T01) for storage before further treatment. The water level in T01 is maintained by an automatic float valve to ensure the tank is always full. The water level is regularly checked to guarantee a constant supply for the system.

2.2. Pre-Filter Column (T02)

Water is pumped through the coarse filter pump (WP01-1/2) and flows into the pre-filter column (T02) via an auto valve. The water passes through filter materials, then moves to the central distribution pipe and continues to the clean water collection pipe. After some time, the auto valve triggers a backwash and discharges wastewater to the raw water treatment system. Water from the pre-filter column flows through the auto valve into the multi-purpose filter column.

2.3. Multi-Purpose Filter Column (T03)

Water from the pre-filter column passes through the auto valve and enters the multi-purpose filter column (T03), where it flows through layers of gravel, sand, activated carbon (AC), and DMI. The water then moves to the central pipe and is released through the clean water outlet of the auto valve. Activated carbon helps to treat iron, organic matter, colorants, and heavy metals. After a period of operation, the auto valve initiates a backwash and discharges the wastewater. The water, after passing through the multi-purpose filter column, moves into the ion exchange filter column.

2.4. Ion Exchange Filter Column (T04)

Water from the multi-purpose filter column passes through the auto valve and enters the ion exchange filter column (T04). The water flows downwards through ion exchange resin beads. After backwashing, the system is regenerated with salt and performs another backwash. The ion exchange beads capture calcium (Ca²⁺) and magnesium (Mg²⁺) ions, softening the water.

2.5. Regeneration Solution Tank (CT01)

The brine from the softening tank (CT01) is drawn into the ion exchange filter column's auto valve and soaked for 45-60 minutes. The regeneration process then begins, discharging magnesium chloride (MgCl₂) and calcium chloride (CaCl₂) ions, which are flushed out to the wastewater system.

2.6. Softened Water Tank (T05)

After passing through the ion exchange filter column (T04), the water enters the softened water tank (T05), where it is stored. A float valve in the tank ensures the water level remains within a safe range, providing sufficient water for the fine filtration and RO systems. The water then moves to the fine filter column.

2.7. Fine Filter Column (T06)

Water enters the fine filter tank and is pumped into the fine filter column (T06) via an intermediate pump (WP05-1/2) under the action of the float signal. The water then passes through filtration fabric with a pore size of 1 micron, entering the filter column and exiting through the clean water collection pipe. Contaminants, impurities, odors, toxic chemicals, and chlorine are retained on the filter surface. Over time, the filter core is cleaned with acid or base or replaced entirely.

2.8. RO Filtration (T07)

Water from the fine filter column is pumped into the RO filtration system via two high-pressure RO filter pumps (FWP06). The water passes through membrane layers and fibers, then is absorbed into the distribution pipe and exits through the clean water pipe. The RO membrane only allows pure water molecules to pass through, while impurities, salts, dissolved metals, organic compounds, and microorganisms are trapped on the membrane's surface. These impurities are flushed out during the filtration process, ensuring the membrane operates continuously.

2.9. Finished Water Tank

After passing through the RO filtration system, the water is stored in the finished water tank (T08). The clean, treated water is then distributed to the factory for use. A float valve is installed in the finished water tank to maintain the water level and ensure there is always an adequate supply of clean RO water meeting the QCVN 06-1:2010/BYT standards.

RO Water Filtration System Designed, Installed, and Implemented by Dai Nam

Dai Nam Environmental Solutions Co., Ltd. is a reputable and professional provider of clean water treatment systems. We are committed to delivering optimal solutions that ensure safe and clean water for both daily use and production.

If your business or factory is looking for a reliable partner to install wastewater treatment, clean water treatment systems, or upgrade existing systems, please contact Dai Nam at 0909 378 796 for expert consultation and answers to all your inquiries. With years of experience in the industry, we provide systems that meet the highest standards and incorporate the latest technology for our valued customers.

.jpg)