Wastewater is an environmental issue that must be addressed promptly to protect human health and the ecosystem. In the field of wastewater treatment, two common methods are widely applied: batch treatment and continuous treatment. Each approach has its own advantages and disadvantages, suitable for different types of industries and specific treatment requirements.

1. Understanding Batch Wastewater Treatment

1.1. What is Batch Wastewater Treatment

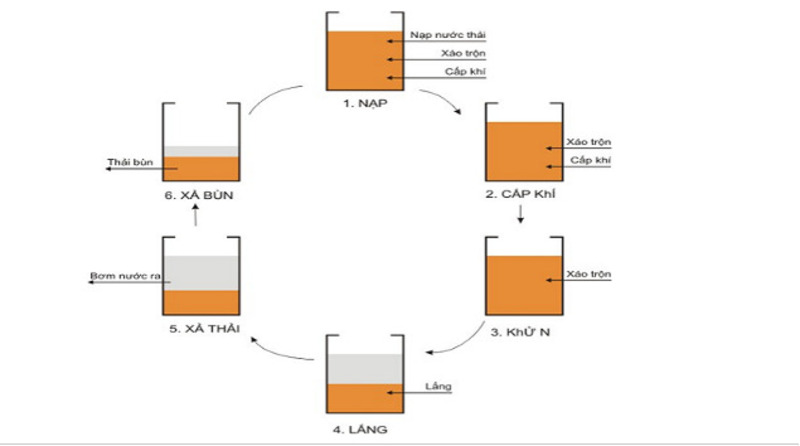

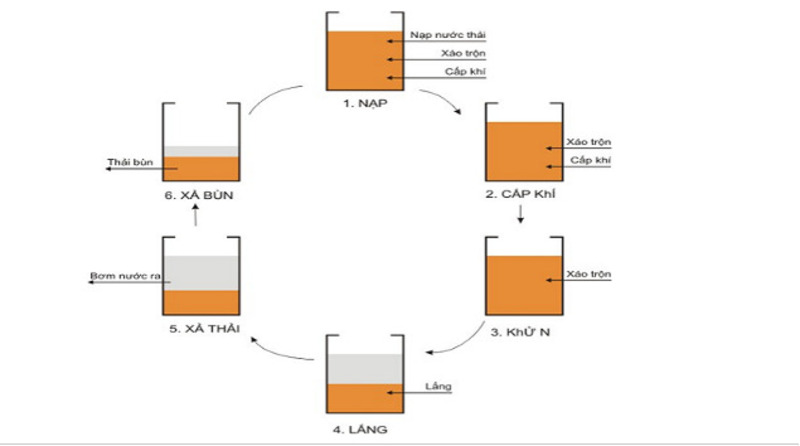

Batch treatment is a wastewater treatment method in which the process is carried out in predefined cycles. This typically includes stages such as receiving wastewater, treatment, and discharge, all conducted within separate cycles. The system requires downtime between cycles for system checks and adjustments to ensure optimal performance.

Batch systems often use biological treatment technologies such as biological reactors, settling tanks, and other methods to target pollutants and hazardous substances in the wastewater.

Batch systems allow rapid adjustment to changing wastewater characteristics

1.2. Advantages and Disadvantages of Batch Wastewater Treatment

Advantages:

-

Lower initial investment: Compared to continuous systems, batch treatment systems typically require less complex infrastructure, reducing capital costs.

-

Ease of operation and maintenance: The simpler setup makes it easier to maintain and repair.

-

Flexible application: Suitable for various wastewater types, from industrial to domestic.

Disadvantages:

-

Unstable performance: Treatment efficiency may vary between cycles, causing fluctuations in the quality of treated water.

-

Longer treatment time: Each cycle must complete before starting the next, reducing throughput efficiency.

2. Understanding Continuous Wastewater Treatment

2.1. What is Continuous Wastewater Treatment?

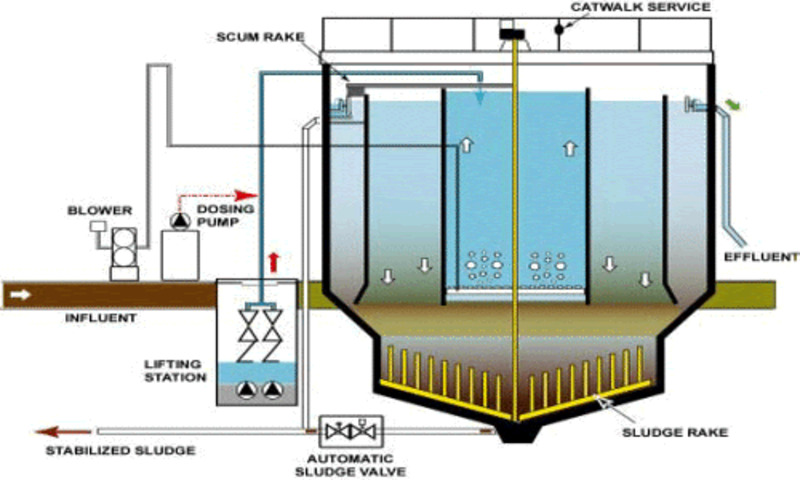

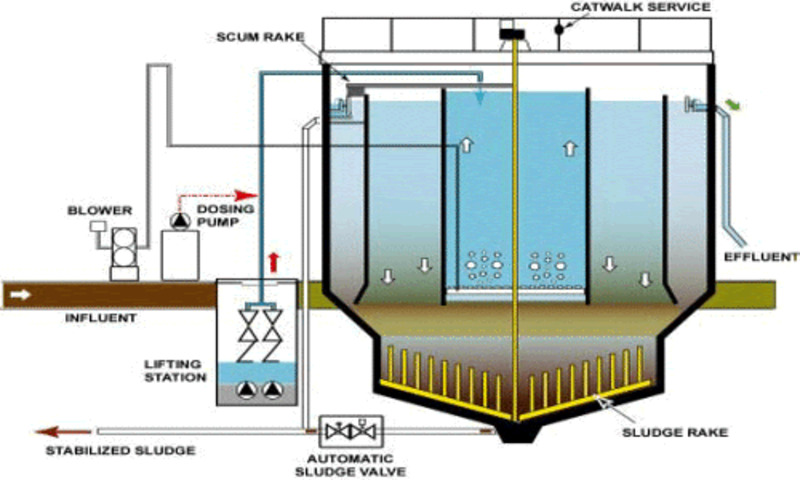

In continuous treatment, wastewater flows constantly through the system, undergoing treatment in a streamlined process without interruptions. This method typically uses technologies such as Continuous Stirred Tank Reactors (CSTR), contact biological tanks, or integrated biofiltration systems.

This method is ideal for industrial zones with high wastewater volumes or where continuous treatment is required.

Modern continuous systems are often integrated with automated monitoring and control technologies for optimal performance

2.2. Advantages and Disadvantages of Continuous Wastewater Treatment

Advantages:

-

Stable performance: Consistent flow ensures steady treatment efficiency and water quality.

-

High processing capacity: Capable of treating large volumes of wastewater quickly.

-

Ideal for large industries: Especially suitable for industrial parks and manufacturing plants with constant wastewater output.

Disadvantages:

-

High initial investment: The design is more complex, requiring modern automation equipment and infrastructure.

-

Advanced operational skills required: Continuous operation demands a skilled team to maintain system stability.

3. Comparison: Batch vs. Continuous Wastewater Treatment

|

|

Batch Treatment

|

Continuous Treatment |

|

System Design |

Includes various separate tanks for mixing, reaction, and settling, each tailored for a specific stage. Allows for better control over individual processes. |

Designed as a flow-based system with integrated stages for biological treatment, settling, and filtration in a compact setup. Requires accurate flow rate calculations. |

|

Operation & Control |

Operates in distinct cycles. Parameters like mixing and settling time can be adjusted. Must pause between cycles, reducing efficiency. |

Runs continuously. Uses sensors and advanced controllers for real-time monitoring and adjustment. Ideal for stable inflows. |

|

Treatment Efficiency |

Allows detailed control for varying wastewater types. Suitable for batch treatment of inconsistent water quality. |

Provides consistent quality output. Suitable for facilities needing high throughput with stable quality. |

|

Cost |

Lower initial cost due to simple design. Higher operational costs due to manual monitoring and downtime. |

Higher initial cost due to automation. Lower long-term costs thanks to efficient operation and reduced downtime. |

|

Application |

Ideal for small to medium facilities, residential areas, or temporary treatment stations. Flexible for fluctuating wastewater. |

Preferred for large-scale plants, industrial parks, or cities with consistent and high wastewater volume. Efficient for long-term use. |

Choosing the right wastewater treatment method depends on various factors such as production scale, wastewater type, budget, and required treatment efficiency.

Batch treatment is suitable for systems with moderate demands and flexible requirements, while continuous treatment is ideal for industrial applications requiring stable, high-volume treatment.

With years of experience in wastewater treatment, Đại Nam proudly offers advanced, efficient, and sustainable solutions. Contact us today for expert consultation and to choose the best wastewater treatment system tailored to your needs.