In industrial wastewater treatment, many harmful organic compounds such as pesticides, dyes, pharmaceuticals, etc., cannot be effectively treated using conventional methods. This is why the Fenton technology — an advanced oxidation process using hydroxyl radicals — is increasingly being applied for its ability to thoroughly break down biologically non-degradable pollutants. The following article will help you better understand the principles, practical applications, and key factors to consider when implementing this technology.

1. Introduction to Fenton Technology

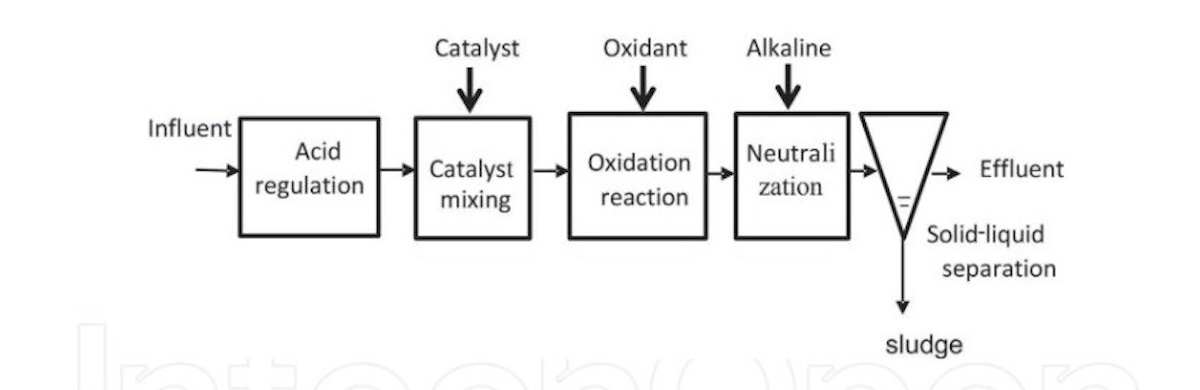

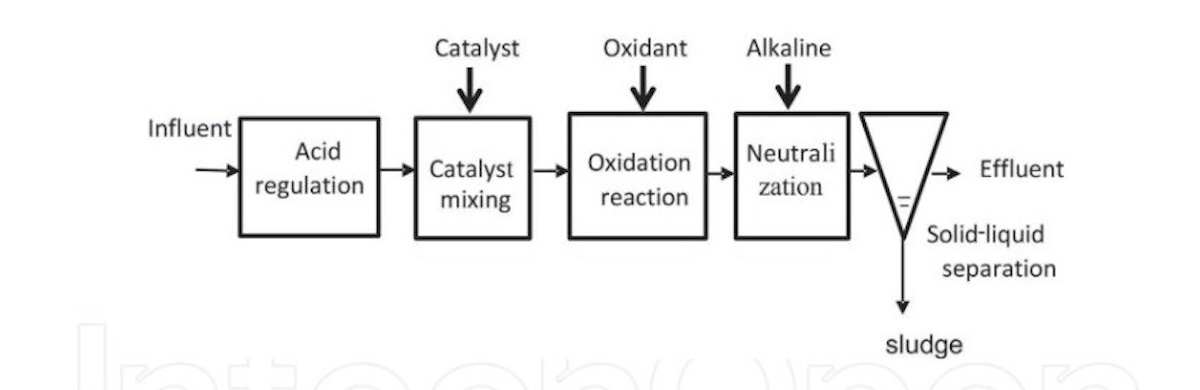

Fenton is an Advanced Oxidation Process (AOP) that utilizes a combination of ferrous ions (Fe²⁺) and hydrogen peroxide (H₂O₂) to generate hydroxyl radicals (•OH). These are powerful oxidants capable of breaking the bonds of stable organic compounds, thereby effectively treating pollutants that resist biological degradation. The core reaction of the Fenton process occurs in a mildly acidic environment (pH ~3) and takes place very rapidly.

The Fenton method is commonly used in industrial wastewater treatment involving dyes, aromatic compounds, pesticides, surfactants, or pharmaceuticals. Its key advantages include independence from microbial activity, high effectiveness with toxic substances, and short reaction times. However, for optimal performance, the Fenton system must be strictly controlled in terms of pH, chemical ratios, and management of the resulting iron sludge.

Introduction to Fenton technology in wastewater treatment. What is it?

2. Factors Affecting the Efficiency of the Fenton Process

2.1 pH Conditions

pH plays a crucial role in the Fenton reaction. The optimal range is usually between 2.5 and 3.5. If the pH is too low (<2), Fe²⁺ may convert too quickly to Fe³⁺, reducing the production of •OH radicals. Conversely, at high pH levels (>4), hydrogen peroxide decomposes into water and oxygen without producing hydroxyl radicals, while iron ions may precipitate as iron hydroxide, hindering the reaction process.

2.2 Temperature

Temperature directly influences the rate of the oxidation reaction. Within the 20–50°C range, higher temperatures accelerate the reaction and increase pollutant degradation. However, temperatures above 50°C cause hydrogen peroxide to decompose rapidly into water and oxygen, reducing •OH production and wasting chemicals. Therefore, temperature must be managed based on wastewater characteristics and operational conditions.

2.3 Molar Ratio of Fe²⁺/H₂O₂

The molar ratio of ferrous ions (Fe²⁺) to hydrogen peroxide (H₂O₂) is a critical factor in determining the amount of hydroxyl radicals generated. Typical ratios range from 1:5 to 1:10 depending on pollution levels. Excessive Fe²⁺ may result in large amounts of iron sludge and unnecessary chemical use. Conversely, an overdosage of H₂O₂ can react with •OH and reduce oxidation efficiency. Optimization through JAR testing or pilot studies is necessary before full-scale application.

3. Practical Applications of Fenton Technology in Wastewater Treatment

3.1 Textile and Dyeing Industry

The textile industry discharges large volumes of wastewater containing dyes, surfactants, organic compounds, and heavy metals. These pollutants are often complex in structure and resistant to microbial degradation. Fenton is effectively applied to remove color, reduce COD, and break down hard-to-degrade compounds, improving downstream biological treatment. In many cases, Fenton is used as a final treatment step to ensure compliance with QCVN 13:2015/BTNMT.

3.2 Pharmaceutical Industry

Wastewater from pharmaceutical manufacturing contains antibiotics, hormones, stabilizers, and organic solvents. These substances are both biologically resistant and environmentally harmful if not treated thoroughly. Fenton helps oxidize these hazardous compounds into more biodegradable forms and can achieve complete removal when combined with membrane filtration or adsorption techniques.

3.3 Chemical Industry

Chemical manufacturing — particularly pesticides, dyes, and industrial solvents — produces heavily polluted wastewater with aromatic compounds, chemically stable substances, and nitro, phenolic, or chlorinated organics. With its high oxidation potential, Fenton is one of the few technologies capable of treating these pollutants effectively without the high energy demand of ozone or UV systems.

3.4 Hospitals and Laboratories

Hospital and laboratory wastewater contains bacteria, residual pharmaceuticals, disinfectants, and reagents. The Fenton process not only reduces COD and pharmaceutical residues but also contributes to disinfection due to its powerful oxidizing radicals. It is often used as a post-biological treatment, especially in systems with strict discharge standards.

Applications of Fenton technology in wastewater treatment

4. Advantages and Limitations of the Fenton Method

4.1 Advantages

-

Destroys persistent toxic compounds: Fenton can break down stable organic pollutants like phenols, pesticides, pharmaceuticals, and industrial dyes, which conventional biological treatment cannot fully remove.

-

No reliance on microorganisms: Since it’s a chemical process, Fenton is more stable in toxic or variable environments.

-

Fast reactions and high efficiency: Hydroxyl radicals form almost instantly when Fe²⁺ meets H₂O₂, allowing rapid removal of COD, color, and pollutants — suitable for applications requiring quick treatment.

4.2 Limitations

-

Strict pH control required: The process only works efficiently within a narrow pH range (2.5–3.5). Any deviation reduces hydroxyl radical formation and treatment efficiency.

-

Iron sludge generation: Iron precipitates must be properly handled to avoid operational and environmental issues.

-

Relatively high chemical cost: H₂O₂ and iron salts are consumables that can become costly when treating heavily polluted wastewater, especially without optimization.

Fenton technology is a powerful and effective solution for treating wastewater with high pollutant loads and persistent compounds. However, achieving optimal efficiency requires tight control of parameters such as pH, temperature, and chemical dosage. With hands-on experience and a professional engineering team, Đại Nam Enviro is ready to support businesses in consulting, designing, and implementing wastewater treatment systems using safe, efficient, and cost-effective technologies.