Currently, the demand for effective and sustainable wastewater treatment has become a top priority for many countries as well as businesses. One of the widely applied solutions today is the biological filter tank. This wastewater treatment technology is based on the activity of microorganisms, which not only brings high efficiency in removing organic matter but is also environmentally friendly and cost-saving. With diverse designs, biological filter tanks are suitable for many different treatment scales, from households, residential areas to industrial plants.

A biological filter tank is a wastewater treatment facility that relies on the activity of microorganisms to decompose organic matter and pollutants in the water. Inside the tank, microorganisms are either fixed on the filter media or exist in suspension, thereby forming a biological film. When wastewater passes through, contaminants are retained and decomposed by the microorganisms into harmless substances such as CO₂, H₂O, and biological sludge. This is an environmentally friendly method, energy-saving, and widely applied in both domestic and industrial wastewater treatment.

Currently, the basic operating principle of biological filter tanks is as follows:

Learn about biological filters in wastewater treatment systems

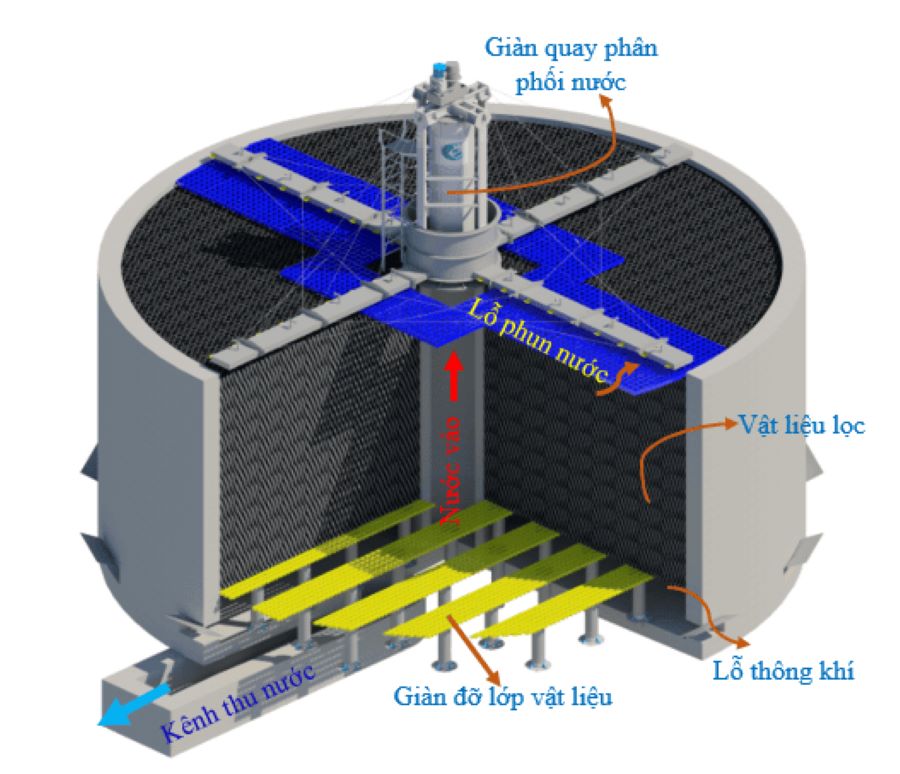

In a biological filter tank system, the main components usually include:

The trickling filter is a type of tank where wastewater is distributed in streams or droplets over a layer of filter media such as stones, gravel, or plastic carriers. On the surface of these materials, a microbial film develops and decomposes the organic matter present in the water. The main advantage of this type is easy operation, low energy consumption, and high efficiency in domestic wastewater treatment. However, it requires a relatively large construction area and regular maintenance to avoid clogging of the filter media.

In a submerged biofilter, the entire filter media layer is immersed in wastewater. An aeration system is installed to provide oxygen for the microorganisms attached to the media surface. This type usually offers high treatment efficiency as microorganisms are always in direct contact with wastewater, and the aeration process is easier to control. Submerged biofilters are suitable for medium and small-capacity treatment plants but consume more energy due to the continuous aeration requirement compared to trickling filters.

The non-submerged biofilter operates on the principle that wastewater only contacts part of the filter media instead of being fully immersed. Thanks to this structure, better ventilation is maintained inside the tank, allowing natural oxygen supply for organic matter decomposition. Its advantage is energy saving as it depends less on aeration systems. However, its treatment efficiency is generally lower than submerged biofilters because the contact area between wastewater and microorganisms is limited.

The high-rate biofilter is an advanced version capable of handling large volumes and high organic loads. The wastewater distribution and aeration systems in the tank are optimally designed to accelerate pollutant degradation. Its outstanding advantage is that it requires a smaller construction area than traditional trickling filters while maintaining stable treatment performance even with fluctuating wastewater flow. This type is widely applied in industrial wastewater treatment with high organic loads but requires higher initial investment and more complex operation.

Update the most widely used biological filter tanks today

Biological filter tanks play an important role in modern wastewater treatment systems due to their sustainability, efficiency, and environmental friendliness. With various forms such as trickling filters, submerged biofilters, non-submerged biofilters, and high-rate biofilters, this technology can meet diverse treatment demands from domestic to industrial applications, aiming to enhance efficiency, optimize costs, and contribute to building a cleaner living environment.