In the field of wastewater treatment, the demand for space-saving solutions and improved treatment efficiency is increasing. The Lamella Settler, also known as an inclined plate settler, is one of the advanced technologies that meets both of these criteria. With a special design consisting of inclined plates arranged in parallel, this system increases the settling surface area, shortens treatment time, and enhances the removal of suspended solids. This article will provide a detailed look into its structure, operation, and advantages.

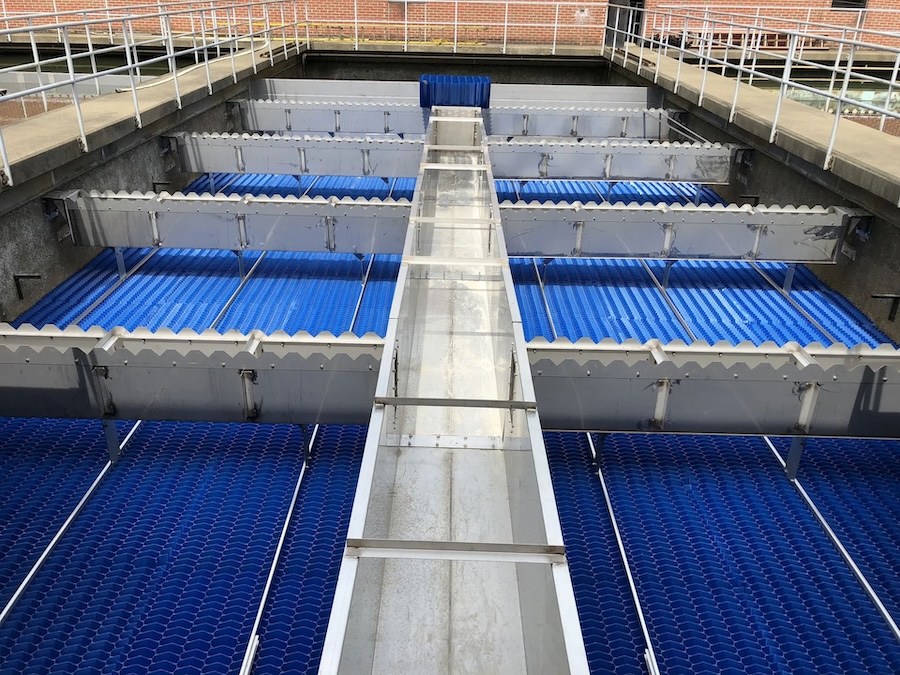

The Lamella Settler is an improved type of settling tank in which the lamella plates are arranged inclined and parallel. This design creates multiple separate settling layers, significantly increasing the contact area between the water flow and the plate surfaces, thereby improving the efficiency of the separation process.

Thanks to its unique structure, the Lamella Settler improves the removal efficiency of suspended solids compared to traditional settling tanks, while saving construction space. This system is widely used in water supply treatment, wastewater treatment, and processes requiring quick sludge–sediment separation. Currently, it is applied in the following water treatment processes:

Lamella Settler allows improved suspended solids removal efficiency

Basically, the Lamella Settler has a structure similar to a traditional settling tank, consisting of three main zones. The first is the inlet distribution chamber, where the wastewater enters the system. Its proper design helps evenly distribute the flow, improving settling efficiency. In many systems, this zone is combined with a coagulation–flocculation unit to enhance impurity removal.

Next is the settling zone, where lamella plates are arranged at an angle of 45° to 60° from the horizontal to increase the contact surface area and shorten the settling path. After this process, larger particles move down to the sludge collection zone at the tank bottom. This is where flocs settle under the influence of gravity, making them easy to collect and treat.

Located at the tank inlet, this unit distributes the water flow evenly before it reaches the lamella plates. Proper distribution ensures stable flow and optimizes settling efficiency.

The lamella plates are usually made from PVC, PP, FRP, or stainless steel for durability and corrosion resistance. They are inclined at an angle of 55°–60° from the horizontal, with a length of about 1–2 m, thickness from 2–5 mm, and spacing between plates ranging from 50–80 mm. This design increases contact surface area and shortens the settling time.

The clarified water after passing through the settling zone is directed into channels or collection pipes to ensure it leaves the tank without carrying residual solids.

Located at the tank bottom, this zone often has a hopper or V-shape to concentrate the settled sludge for easy collection and treatment.

Sludge is removed from the tank through valves or periodic pumping. This mechanism helps maintain available sludge storage space and ensures stable treatment efficiency.

The Lamella Settler significantly increases the settling surface area by using inclined plates, enabling faster solids separation. As a result, for the same treatment capacity, the construction footprint can be much smaller than traditional settling tanks. This is especially suitable for facilities with limited space.

Thanks to its optimized design, the tank can remove up to 80–90% of total suspended solids (TSS) before the water enters the filtration stage. The lamella plates shorten the settling path and reduce retention time while maintaining treatment efficiency. This helps improve the quality of treated water and reduces the load on subsequent processes.

The tank structure is often designed in modules, allowing quick assembly and easy adjustment to meet actual needs. The lamella plates can be removed for cleaning or replacement when necessary, reducing maintenance time and ensuring long-term stable operation.

Advantages of Lamella Settler

The Lamella Settler is a significant advancement in settling technology, delivering superior treatment efficiency while optimizing installation space. With its smart design of inclined plates, the system not only improves solids separation efficiency but also reduces long-term operating costs. With its outstanding advantages and flexible application, it promises to continue playing an important role in modern water treatment projects.