Dai Nam Environmental Solutions Co., Ltd. has successfully completed the construction and installation of a wastewater treatment system at Phu An Thanh Industrial Park, Long An, with a capacity of 360 m³/day-night. The system is designed to ensure treated effluent meets Vietnam’s National Technical Regulation on Industrial Wastewater – QCVN 40:2011/BTNMT, Column B before discharging into the central drainage connection of the industrial park.

1. Project Information

-

Project Name: Wastewater Treatment System – Phu An Thanh Industrial Park, Long An

-

Contractor: Dai Nam Environmental Solutions Co., Ltd.

-

Location: Phu An Thanh Industrial Park, Provincial Road 830, An Thanh Commune, Ben Luc District, Long An Province, Vietnam

-

Treatment Capacity: 360 m³/day-night

-

Effluent Standard: QCVN 40:2011/BTNMT, Column B – National Technical Regulation on Industrial Wastewater

Wastewater Treatment System Control Room of the Project

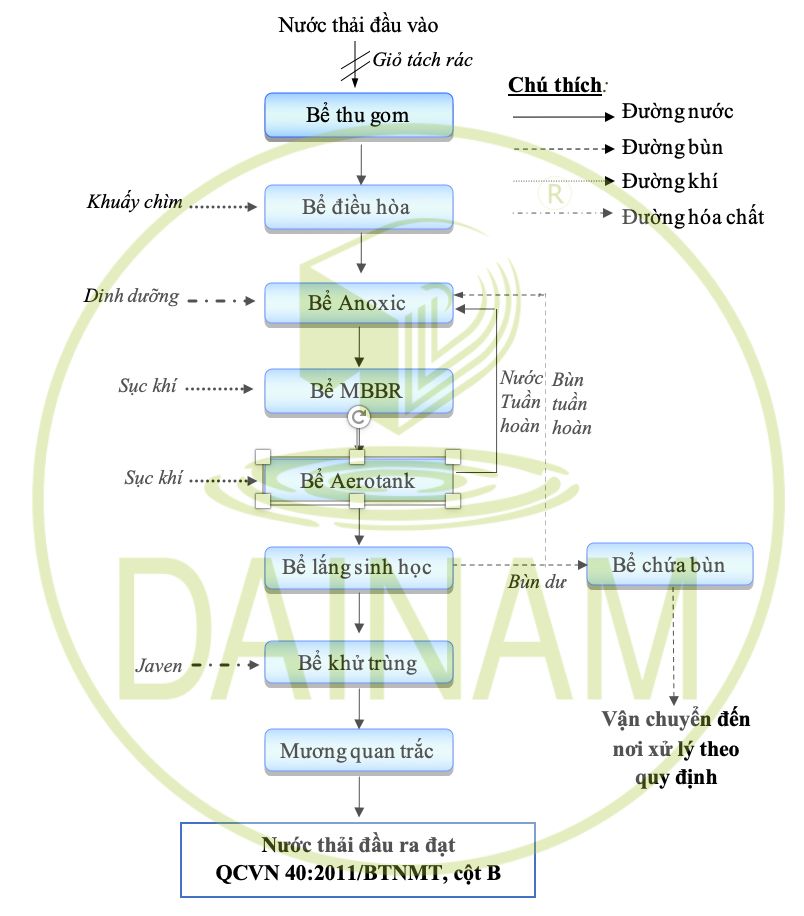

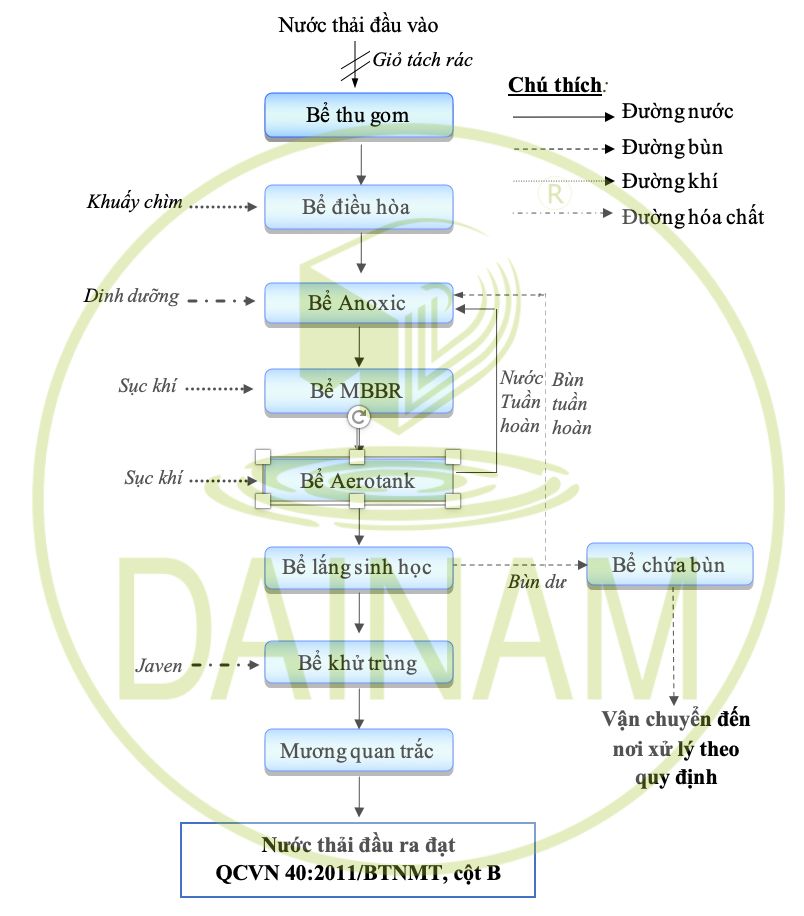

2. Technology Process Overview

-

Collection Tank: Incoming wastewater is first passed through a screening basket to remove large debris and solids, preventing pump blockages and pipeline clogging.

-

Equalization Tank: This tank is designed with sufficient retention time to balance flow rate and stabilize pollutant concentrations before entering the treatment stages.

-

Anoxic Tank: This is where the denitrification process takes place, effectively removing nitrates from the wastewater.

-

Aerobic Biological Tank (MBBR + Aerotank): Combining Moving Bed Biofilm Reactor (MBBR) technology with Aerotank, this stage uses suspended biofilm carriers to promote the growth of aerobic microorganisms. These microbes degrade organic matter and help separate sludge from treated water.

-

Secondary Clarifier: This tank performs the solid-liquid separation, allowing biomass (activated sludge) to settle and be removed from the treated effluent.

-

Disinfection Tank: This tank holds the final effluent and disinfects it using chlorine-based chemicals, effectively eliminating harmful pathogens before discharge.

-

Monitoring Channel (Measuring Flume): Built to monitor and record water quality parameters such as pH, COD, TSS, and flow rate, this channel is equipped with automated sensors that transmit data daily to the Department of Natural Resources and Environment, ensuring high accuracy.

-

Sludge Holding Tank: Excess sludge from the clarifier is pumped into this tank, where it undergoes biological degradation and volume reduction.

-

Odor Control System: This system captures and treats odors and vapors emitted from the treatment units, ensuring no unpleasant smells impact the surrounding environment.

Wastewater Treatment System Diagram

Control Panel for the Wastewater Treatment System of the Project

Aeration Blower for Providing High Oxygen Levels to Support Microbial Growth and Development

Aeration Blower for Providing High Oxygen Levels to Support Microbial Growth and Development

Wastewater Treatment Technology Process

3. Advantages of the Wastewater Treatment System

Wastewater generated from factory operations is initially pretreated in septic tanks and then collected into a centralized wastewater treatment system. The system is designed with essential treatment units, offering a range of technical and operational advantages.

3.1 Process Technology Advantages

-

The system uses widely adopted and proven treatment technologies, ensuring consistent effluent quality that meets environmental standards.

-

It combines anoxic and aerobic treatment processes, effectively reducing organic compounds (nitrogen indices) and removing phosphorus through excess sludge discharge.

-

The sludge holding tank is designed with a large capacity to store and stabilize sludge, minimizing solid content and volume.

-

Activated carbon filtration is applied for low-cost operation while efficiently removing odors and adsorbing toxic substances, protecting both human health and the environment.

-

The system is equipped with automated controls, eliminating the need for on-site operators and reducing risks from human error or system failures.

3.2 System Design Advantages

-

The layout allows for future capacity expansion, offering flexibility for increased wastewater loads.

-

Treatment units are constructed in modular, integrated blocks, which help reduce construction and pipeline connection costs.

-

Energy consumption is optimized by leveraging gravitational flow and pressure differences, reducing pumping needs and operational costs.

-

Block-type bio-carriers are used to improve treatment efficiency and eliminate the risk of clogging, ensuring long-term stable operation.

Visual Representation of an Underground Wastewater Treatment System Post-Construction

At Dai Nam Environmental Wastewater Treatment Company, we are committed to delivering comprehensive and safe wastewater treatment solutions for industrial zones, manufacturing facilities, residential areas, healthcare centers, livestock farms, and more.

With over 10 years of experience in the industry and a team of highly qualified experts, we are proud to be a trusted partner for numerous businesses and organizations across Vietnam.

For more information and a free consultation with our expert team, contact us today via our Hotline: 0909 378 796.

Aeration Blower for Providing High Oxygen Levels to Support Microbial Growth and Development

Aeration Blower for Providing High Oxygen Levels to Support Microbial Growth and Development

.jpg)