The plastic manufacturing industry provides many essential products serving daily life and industry. However, along with that development comes a large amount of wastewater generated during the production process. Wastewater from the plastic industry contains many complex pollutants such as industrial grease, chemical additives, microplastics, and hard-to-decompose organic compounds. If not properly treated, it will cause serious impacts on the environment and community health. Therefore, this article will introduce advanced plastic manufacturing wastewater treatment solutions suitable for the specific characteristics of the current plastic manufacturing industry.

The plastic manufacturing industry is an important industrial sector, providing a variety of products for daily life and production, from packaging, plastic bottles, and construction materials to technical components. However, during the production process, especially in shaping, cooling, and equipment cleaning stages, a large amount of wastewater containing many impurities is generated. This wastewater often contains suspended solids, industrial grease, chemical additives, organic solvents, and microplastics. Depending on raw materials and production technology, wastewater can be slightly alkaline or acidic, with high COD and BOD levels, and also containing hard-to-decompose organic compounds.

If not treated to standard, wastewater from plastic manufacturing will cause many negative environmental impacts. Organic substances and toxic chemicals can degrade water quality, affect aquatic ecosystems, and impact human health through the food chain. Microplastics can accumulate long-term in the environment and organisms, causing serious consequences for marine and soil environments. In addition, untreated wastewater can produce unpleasant odors, affect the lives of surrounding residents, and violate environmental protection regulations.

Plastic manufacturing wastewater causes many negative environmental impacts, leading to serious environmental consequences

In plastic manufacturing, wastewater is generated from many different stages, each with its own characteristics and level of pollution. Identifying the sources is an important basis for designing an effective and suitable treatment system. The main sources of wastewater include:

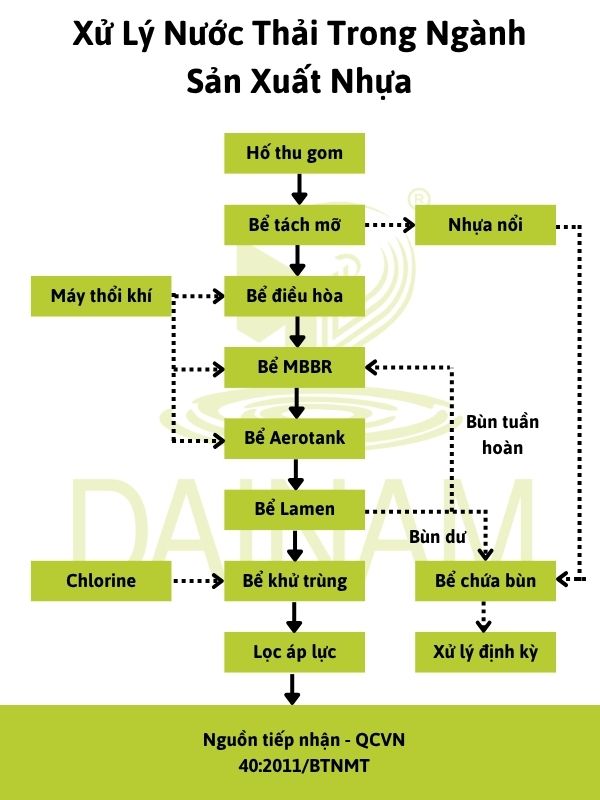

The collection pit receives all wastewater from the sources in the factory. Its main function is to gather wastewater, remove large solid debris using bar screens or mesh filters, and protect the downstream treatment units. The pit is usually designed to have an appropriate depth to avoid excessive sludge accumulation and ensure stable pumping.

The grease trap works on the principle of density difference between water and oil/grease. Here, oil, grease, and floating plastic are retained on the surface and periodically removed, preventing clogging and reduced biological treatment efficiency. The trap often has partitions and special flow paths to optimize separation efficiency.

The equalization tank balances the flow rate and pollutant concentration of wastewater, helping the treatment system operate more stably. It is equipped with an air blower for mixing, preventing sedimentation and reducing odors. This ensures that the pollutant load entering the biological units is uniform, increasing treatment efficiency.

The MBBR tank uses moving plastic carriers for microorganisms to attach and form biofilm. When wastewater comes into contact with the carriers, microorganisms decompose organic substances, reducing COD and BOD. Continuous aeration increases dissolved oxygen, maintaining aerobic microorganism activity.

The Aerotank is an aerobic biological treatment unit where suspended microorganisms decompose dissolved organic matter in wastewater. With continuous aeration, microorganisms oxidize and convert organic matter into CO₂, water, and new biomass. A portion of the activated sludge is recycled back to the Aerotank to maintain microorganism density.

The Lamella settling tank is designed with inclined plates to increase surface area and shorten settling time. Sludge and suspended particles settle to the bottom, while clear water flows to the next stage. The lamella structure allows for high efficiency in a smaller footprint.

After settling, wastewater flows to the intermediate tank where disinfection is performed using chlorine or other disinfectants. The purpose is to kill pathogens, ensuring the effluent meets QCVN 40:2011/BTNMT discharge standards before being released into the environment.

The pressure filter is an advanced treatment step to remove suspended solids, color, and residual impurities after disinfection. The system uses filter media such as quartz sand, activated carbon, gravel, and can include ion exchange material to treat heavy metals. Water after filtration is highly clear and meets strict discharge requirements.

The sludge holding tank stores sludge generated from the settling and biological treatment stages. Sludge is stored temporarily before being periodically treated according to regulations. Proper sludge management avoids secondary pollution and ensures compliance with hazardous waste management regulations.

Treating plastic manufacturing wastewater is not only a mandatory legal requirement but also a corporate responsibility toward the community and the environment. Applying a proper treatment process—from collection, grease separation, and flow equalization to biological treatment, settling, and disinfection—ensures that the effluent meets QCVN 40:2011/BTNMT standards. At the same time, optimizing operation, reducing wastewater volume, and reusing treated water will help reduce production costs, improve economic efficiency, and move toward a green and sustainable development goal for the plastic industry.

Plastic manufacturing wastewater treatment process meeting QCVN 40:2011/BTNMT standards

Treating plastic manufacturing wastewater is not only a mandatory legal requirement but also a responsibility of enterprises toward the environment. A proper treatment process will ensure that the effluent meets QCVN 40:2011/BTNMT standards. At the same time, optimized design and construction solutions provided by Đại Nam will help reduce production costs, improve economic efficiency, and move toward the goal of green and sustainable development for the plastic industry.