During wastewater treatment, the removal of grease, suspended solids, and difficult-to-settle impurities is a major challenge for many industries. One widely applied solution today is the flotation method. This technology relies on the principle of generating ultra-fine air bubbles that attach to pollutants and lift them to the surface, allowing easy separation from the water. With high treatment efficiency, short operation time, and flexible integration with other processes, flotation has become an optimal choice for both domestic and industrial wastewater treatment systems.

1. Introduction to the Flotation Method

Flotation is a wastewater treatment technique based on creating micro-bubbles that collect and carry suspended solids, grease, or insoluble impurities to the surface. From there, these obstructive components are separated from the water, making it clearer and cleaner. This is not merely a mechanical filtration step but also a process that enhances the overall quality of treated water.

The strength of flotation lies in its ability to rapidly remove pollutants, thereby minimizing adverse impacts on the environment and human health. When applied in practice, this method helps enterprises optimize costs and shorten treatment time compared with many other technologies, while still ensuring high purification efficiency.

Basic understanding of the flotation method

2. Basic Working Principle

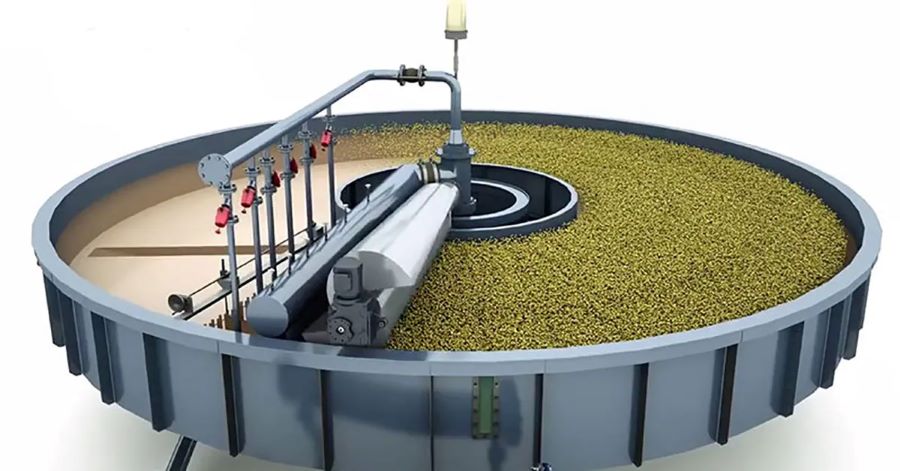

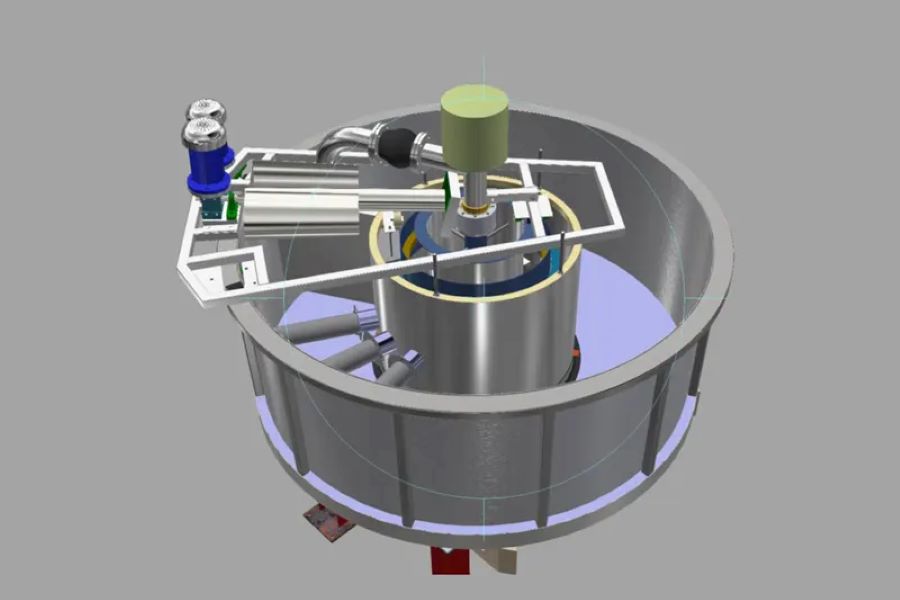

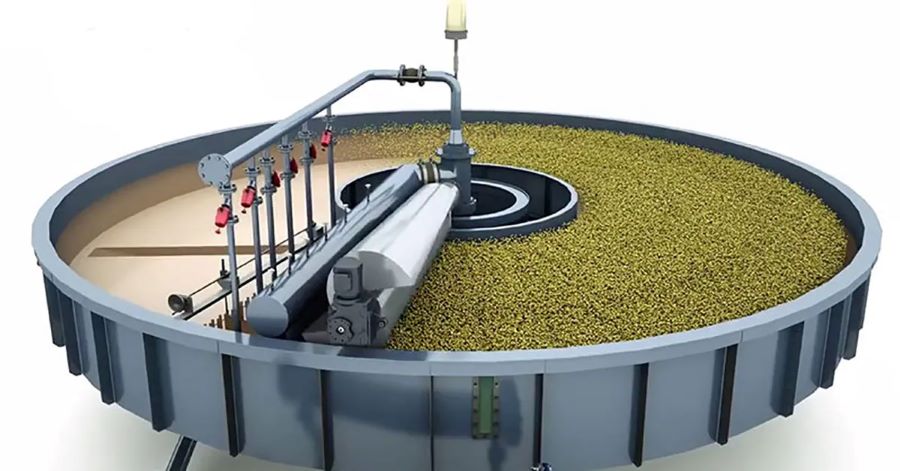

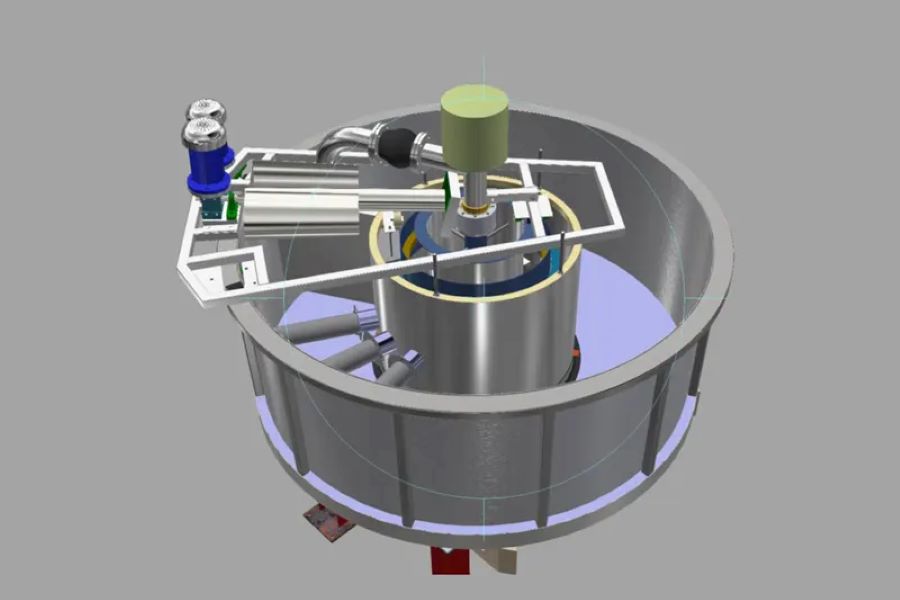

The core of flotation technology is utilizing pressure differences to generate extremely fine air bubbles. When wastewater is saturated with air at high pressure and then suddenly released to atmospheric pressure, countless micro-bubbles form. These bubbles adhere to solid particles, grease, and suspended impurities, pulling them upward to the water surface for removal.

The process can be described through the following steps:

- A pressure pump injects wastewater into the air-dissolving tank.

- A compressor adds air into the flow, creating a gas-saturated solution.

- When the flow passes through a pressure-reducing valve, the drop in pressure releases the air into tiny bubbles.

- In the flotation chamber, bubbles attach to pollutants and gradually float to the surface.

- A layer of scum accumulates at the top, which is periodically scraped off and sent to a sludge tank for further treatment.

- Heavy particles that do not attach to bubbles settle to the bottom and are removed via sludge pumps.

3. Advantages and Disadvantages of the Flotation Method

3.1 Advantages

- High treatment efficiency: Flotation quickly removes grease, suspended solids, and difficult-to-settle impurities, improving effluent quality compared with traditional mechanical methods.

- Space saving: Flotation tanks are compact and have short processing times, making them suitable for sites with limited space.

- Ease of operation: Bubble generation and scum collection are simple and easy to monitor. Operators can easily adjust parameters to optimize efficiency.

- Flexible integration: Flotation can be combined with coagulation–flocculation processes to enhance solid separation, expanding its applicability across various wastewater types.

- Wide application: The technology suits both domestic and industrial wastewater, including food processing, seafood, and textile dyeing sectors, making it widely used in practice.

3.2 Disadvantages

- Limited removal scope: The method works well for insoluble or suspended materials but requires additional biological or physico-chemical steps for dissolved pollutants.

- Energy consumption: The system needs compressors and pressure pumps to maintain airflow, which increases electricity use and operating costs.

- Higher operating cost: Compared with gravity sedimentation tanks, flotation systems require more equipment investment and maintenance, leading to higher long-term costs.

- Scum management: The surface sludge and grease must be periodically scraped, collected, and treated, adding extra cost and management effort.

- Technical requirements: For optimal performance, the design and operation of the flotation tank must be precise. Any deviation may reduce bubble generation or separation efficiency.

4. Common Flotation Methods

- Dissolved Air Flotation (DAF): Wastewater is pressurized and mixed with air at high pressure, then rapidly depressurized to form numerous fine bubbles that attach to contaminants and lift them to the surface.

- Mechanical Flotation: Uses impellers or pumps to directly disperse air into the wastewater. As the impeller rotates, small vortices form bubbles—the finer the bubbles, the better the separation.

- Porous Media Flotation: Air is blown through a porous membrane, creating tiny bubbles. Efficiency depends on pore size, air pressure, and contact time.

- Chemical Flotation: Gas produced during chemical reactions forms bubbles that attach to suspended particles, causing them to rise. This simple method can also recover valuable metals but requires more chemical input.

- Electroflotation: Based on electrolysis, hydrogen and oxygen gases act as flotation bubbles. This process offers fast treatment and significantly reduces residual floc concentration.

- Biological Flotation: Commonly used for sludge thickening or removing suspended solids in domestic wastewater. It helps reduce sludge volume before further treatment.

- Natural Flotation: Utilizes the density difference between oil, grease, and water to separate them without complex equipment, usually applied in preliminary treatment stages.

Enhancing Water Quality through Flotation Techniques

Flotation is not just a simple solid-liquid separation step—it plays a crucial role in improving post-treatment water quality. Thanks to its effectiveness in removing grease, suspended solids, and difficult-to-treat impurities, this technology has proven its importance across multiple industries. Although it still poses challenges in terms of cost and technical requirements, ongoing innovations and integration with advanced methods ensure that flotation will continue to serve as a key process in modern wastewater treatment systems.