Inspect each mechanical component as specified by the manufacturer.

Inspect and replenish disinfectant chemicals such as chlorine or Javel to ensure the treated water output meets Column B or A standards.

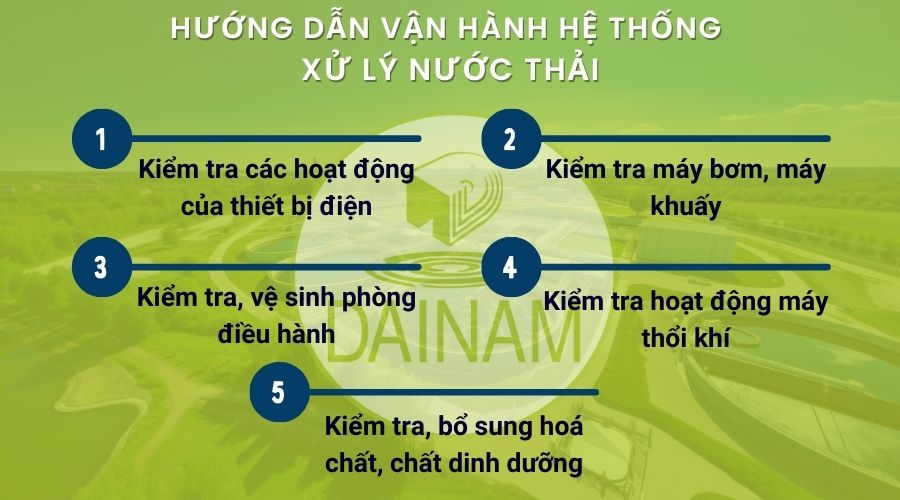

Standard Operating Procedure for a Wastewater Treatment System

In addition to the components mentioned above, wastewater treatment system operators should also inspect several other systems:

Check for leaks in pipelines

Check for leaks in pipelines

Check the quality of the output water

Check the flow rate of chemical dosing pumps and adjust if necessary

Inspect the blower system and adjust the airflow rate if needed

Transport, sludge discharge and sludge analysis

Write an operation report for the wastewater treatment system

Finally, carefully read the operation manual of the wastewater treatment system and the chemical safety data sheets provided by the manufacturer before using any chemicals.

Checklist

Usually, when operating a wastewater treatment system, some facilities only focus on monitoring and measuring wastewater parameters while neglecting the monitoring of operational system parameters. These parameters can help identify the root causes of any issues that arise. Below are the parameters that need attention when operating a wastewater treatment system. Wastewater treatment system operators at factories must frequently monitor these to avoid other incidents related to microbial wastewater treatment systems.

COD, BOD, MLSS (for industrial wastewater to assess whether the activated sludge in the treatment tank is performing well or not)

Total Nitrogen (Total N), Total Phosphorus (Total P)

Biomass volume: SV30 (mg/L) = settled sludge volume after 30 minutes (Experimental Volume = 1 liter)

Sludge Volume Index: SVI (ml/g) = settled biomass volume / biomass concentration

SVI = (SV30 x 1000) / MLSS

50 < SVI < 100 ml/g: best

100 < SVI < 150 ml/g: presence of filamentous bacteria

150 < SVI < 200 ml/g: relatively difficult sludge settling

200 < SVI < 300 ml/g: poor sludge settling

SVI > 300 ml/g: sludge does not settle

Flow rate: ensure a stable flow within a given time unit

pH level: optimal pH for microbial growth ranges from 6.5 – 8.5

Airflow rate in the aerobic tank

Inspect machinery and equipment such as those mentioned above (e.g., air blowers, wastewater pumps, chemical dosing pumps, etc.) to ensure they are functioning properly. Estimate the quality of influent wastewater, check pipeline and electrical systems for equipment, and prepare microbial products for system activation.

* Anaerobic Tank

Typically, to start up an anaerobic biological system, a sufficient amount of wastewater is needed to activate the system. To avoid shock loading during initial operation, the system should receive a mix of 50% wastewater + 50% clean water without disinfectants.

To quickly cultivate microorganisms in the anaerobic tank, seed sludge from a stable operating treatment system is added. Granular anaerobic sludge is considered optimal for system startup.

To support microbial growth and accelerate the operation process, after startup, nutrients and high-quality microbial products such as Microbe Lift, D – Clean are added. The startup period generally takes 4 – 5 weeks or longer depending on sludge concentration and influent wastewater quality. During this phase, the system should be continuously monitored, gradually increasing the volume of wastewater fed into the tank until reaching the design capacity.

* Anoxic Tank

The operation of an anoxic tank is simpler and typically integrated with aerobic treatment processes.

* Aerobic Tank

For aerobic treatment, the startup period is faster compared to anaerobic and anoxic processes, usually taking about 2 – 3 weeks for the system to become stable.

.jpg)

Key Considerations When Starting the Operation of a System

To ensure that the wastewater treatment system operates effectively and meets standards, choosing a professional service provider for system operation is crucial. Dai Nam is one of the most reliable and quality service providers for wastewater treatment system operation in Vietnam.

With a team of experienced engineers and experts, Dai Nam is committed to providing comprehensive solutions for the operation, maintenance, and optimization of wastewater treatment systems, helping businesses save costs and ensure compliance with environmental regulations.

If you are looking for a provider of wastewater treatment system operation services, please contact us at 0909 738 796 for consultation and to have all your questions answered!