Where Does Rubber Wastewater Come From?

Rubber wastewater primarily originates from processes such as bulk latex production, centrifugation latex production, latex processing, and the washing of production lines. Wastewater from the rubber industry typically has a higher flow rate compared to other industries. It also contains high levels of pollutants that are difficult to treat. Therefore, to build an effective wastewater treatment system for the rubber industry, companies responsible for constructing rubber wastewater treatment systems must have the capability, experience, and advanced technology to optimize the system, aiming to minimize both construction and operational costs in the future.

In particular, rubber wastewater has a low pH. Rubber particles in the water have a high density. The sludge produced during the coagulation and crepe rolling stages primarily consists of rubber particles that, after coagulating into large lumps, still contain rubber particles that have coagulated but have not yet fully bonded.

.JPG)

Wastewater from Rubber Latex Processing: A Challenging Wastewater with High BOD, COD, Total N, and P Levels

The pollution concentration of rubber wastewater ranges from 3000 to 6000 mg/l for COD, from 2000 to 4000 mg/l for BOD, and can reach up to 500 mg/l for ammonia and total nitrogen. This makes rubber wastewater particularly difficult to treat. It requires the combination of multiple treatment methods, from chemical to biological processes, to bring the wastewater to acceptable discharge standards.

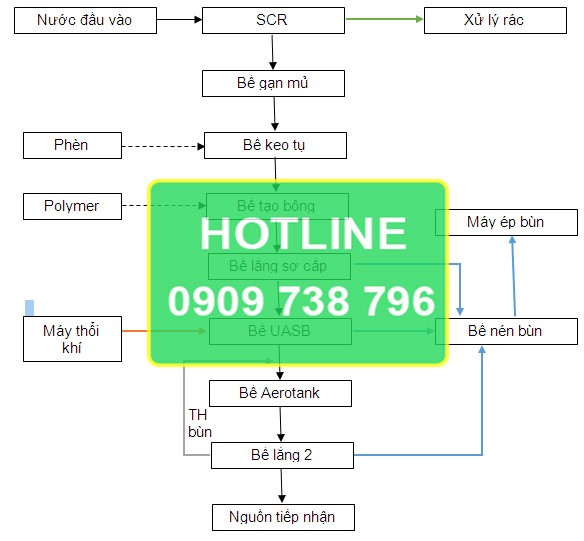

Explanation of Rubber Wastewater Treatment Technology

After production and processing, the rubber wastewater flows through a drainage channel, passing through a bar screen before reaching the coagulation tank. The coarse bar screen is primarily used to remove large debris to prevent clogging of pumps and pipelines in the wastewater treatment system. The suspended latex in the wastewater is removed after passing through the coagulation tank. The wastewater is then directed to the coagulation tank, where flocculation helps reduce the amount of suspended solids and other particles in the wastewater. Notably, the rubber particles that have not fully coagulated are still present in the wastewater. Common chemicals used in this tank include alum and polymer. The pH is also adjusted to optimize performance and create a favorable environment for microorganisms during the biological treatment process.

Standard Rubber Wastewater Treatment Technology Process

After the wastewater has undergone physical-chemical treatment, it is directed to the UASB anaerobic biological tank. The wastewater enters from the bottom of the tank and flows upward, where mechanical mixing is applied to ensure that the treatment reaction between the wastewater and microorganisms occurs. This process significantly reduces the organic substances in the wastewater, resulting in high BOD and COD treatment efficiency. However, the formation of granular sludge takes time and is difficult to control, requiring continuous monitoring and inspection. Afterward, the wastewater is transferred to the primary sedimentation tank.

After passing through the UASB tank, the wastewater is directed to the Aerotank. In this tank, aeration systems create an environment conducive to the growth of activated sludge, mixing the wastewater to facilitate rapid and efficient oxidation reactions. Along the length of the tank, the wastewater is treated almost to the required standards. However, some rubber manufacturers have very high nitrogen content in their wastewater. In these cases, adding biological media in combination with the UASB tank can improve treatment efficiency.

After the wastewater treatment process, it is sent to the secondary sedimentation tank. The sludge from this tank is transferred to the sludge dewatering machine, and part of it is returned to the biological tank.

If your company currently lacks a wastewater treatment system or if your existing system does not meet the discharge standards, has high operational costs but insufficient efficiency, please contact Dai Nam Environmental Company for the best consultation and optimized wastewater treatment solutions.

.JPG)