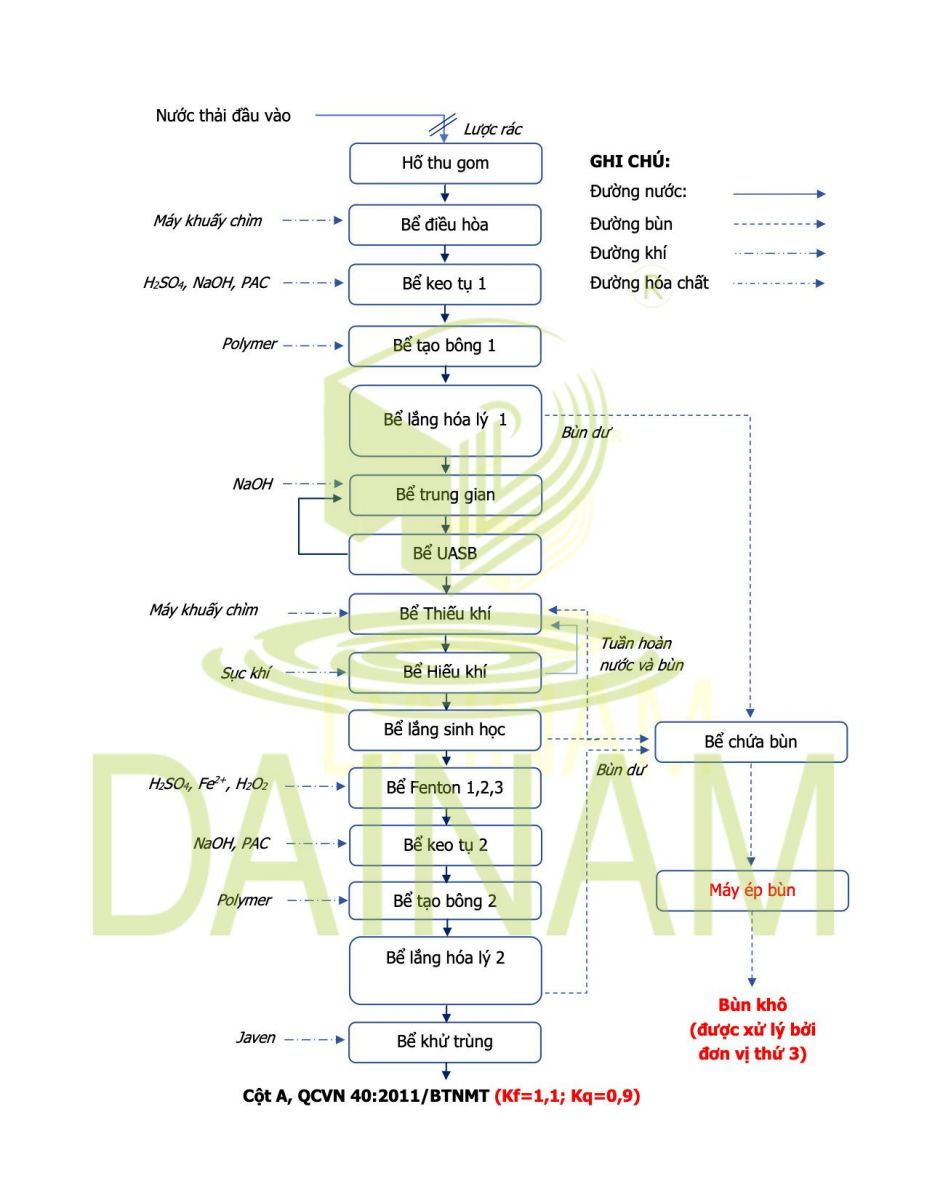

To help enterprises understand the leachate treatment process, Dai Nam Environment provides a detailed outline of each stage below.

Summary of Leachate Wastewater Treatment Process Steps

Summary of Leachate Wastewater Treatment Process Steps

Leachate is collected and flows into a pit, passing through a coarse screen to remove large debris and prevent clogging of downstream components.

Divided into mixing and pumping chambers, these tanks adjust pH and ensure uniform chemical distribution before anaerobic treatment.

In the UASB Tank, wastewater is distributed from bottom to top through an anaerobic sludge layer, where anaerobic decomposition takes place. Organic substances undergo degradation in the following stages:

- Stage 1: Hydrolysis, breaking down high-molecular compounds.

- Stage 2: Acidogenesis.

- Stage 3: Acetogenesis.

- Stage 4: Methanogenesis.

In the Aerobic Tank, two main processes occur as follows:

Nitrification Process:

The nitrification process from nitrogen and ammonia is divided into two steps and involves two types of microorganisms: Nitrosomonas and Nitrobacteria. In the first step, ammonia is converted into nitrite, and in the second step, nitrite is converted into nitrate:

NH4+ + 1.5 O2 → NO2- + 2H+ + H2O

NO2- + 0.5 O2 → NO3-

Nitrosomonas and Nitrobacteria use the energy obtained from these reactions to sustain themselves and synthesize biomass. This process can be summarized with the following equation:

NH4+ + 2 O2 → NO3- + 2H+ + H2O (*)

Organic Matter Oxidation and Degradation Process:

Organic Matter (BOD) + O2 → CO2 + H2O + Energy

New Cell Synthesis:

Organic Matter (BOD) + O2 + NH3 → Microbial Cells + CO2 + H2O + Energy

Endogenous Degradation:

C5H7O2N + O2 → CO2 + H2O + NH3 + Energy

The entire oxidation and synthesis reaction is represented by the following equation:

NH4+ + 1.83 O2 + 1.98 HCO3- → 0.021 C5H7O2N + 0.98 NO3- + 1.041 H2O + 1.326 H2CO3

Furthermore, to prevent the loss of biomass in the aerobic tank, the process of sludge addition is performed by recycling the sludge from the biological settling tank to the Anoxic Tank. After the aerobic tank, the wastewater naturally flows into the biological settling tank.

The Settling Tank is designed to separate microbial sludge particles from the treated water through gravity sedimentation. The biological settling tank is divided into three sections: the clear water section, the settling section, and the sludge storage section.

Water enters the central pipe and is evenly distributed throughout the tank. Under the influence of gravity and flow direction baffles, the microbial sludge particles settle to the bottom, while the clear water moves upward. The clear water is collected through a weir system and flows into the Fenton tanks 1, 2, and 3 for further treatment.

Fenton is an advanced oxidation process used in wastewater treatment. The Fenton process is applied to oxidize hard-to-degrade organic substances. It helps effectively eliminate pollutants, maintaining the effluent quality at a stable level that consistently meets required standards. Additionally, placing the Fenton process after the biological treatment stage helps reduce chemical usage. Due to the strong oxidative power of *OH compared to traditional disinfectants, it also has the ability to completely eliminate common bacteria.

Physicochemical Sedimentation Tank 2: This tank is responsible for settling and separating sludge from wastewater, reducing TSS (Total Suspended Solids). The daily amount of sludge generated will be pumped to the sludge storage tank. The clear water flowing out from the physicochemical sedimentation tank 2 will then proceed to the disinfection tank.

The disinfection tank is responsible for containing the water and disinfecting it to eliminate harmful microorganisms. The chemicals used for disinfection are chlorine-based compounds. After treatment, the wastewater meets the QCVN 40: 2011/BTNMT Column A standards (Kf = 1.1; Kq = 0.9) and is discharged into the receiving water source.

3.13 Sludge Holding Tank

Excess sludge from the biological settling tank, UASB tank, and physicochemical settling tanks 1 and 2 is pumped to the sludge storage tank. Here, the sludge degradation process occurs.

Results of the sludge degradation process:

- Increased solid concentration in the sludge;

- Reduced organic content in the sludge, helping to stabilize it;

- Reduced sludge volume before treatment.

- Periodically, the sludge in the storage tank will be pumped to the sludge dewatering machine for treatment.

For consultation, design, and sewage leachate, industrial, medical, and domestic wastewater treatment systems, please quickly contact Dai Nam Environmental at: 0909 378 796 for suitable options. With successful projects we have carried out and costs optimized, we are sure you will be satisfied.